Forklift Safety Upgrades Save Lives

Forklifts, cranes, conveyor belts and heavy equipment are used in all sorts of industries. From warehouses to farms, grocery stores to factories, this type of equipment makes moving materials easy and efficient.

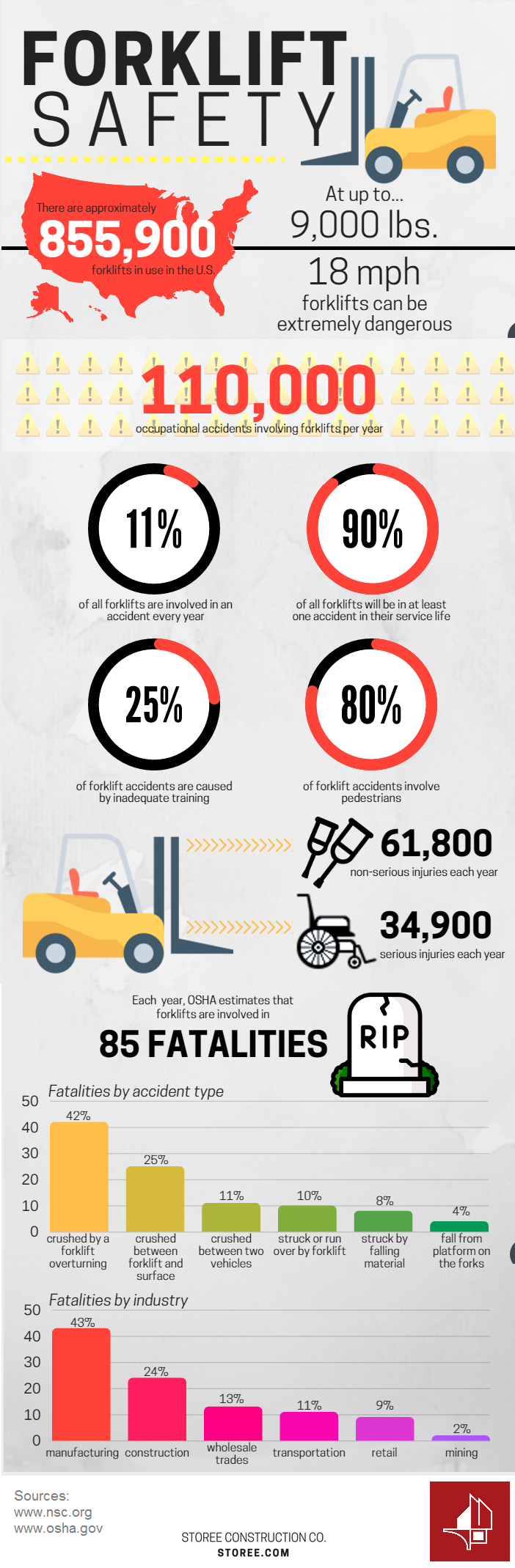

Anywhere there’s heavy equipment however, there are accidents and the need for personal safety equipment on the worksite. Looking at forklifts alone, it’s easy to see that industry needs to take steps to improve forklift safety.

About 900,000 forklifts are in estimated to be in use around the nation. Nearly 35,000 serious forklift accidents happen annually according to OSHA. Almost half of those accidents take place in manufacturing facilities. Construction, warehouses and transportation also see their share of forklift collisions.

Some accidents are due to driver error. Inadequate training and poor forklift safety design also cause mishaps and injuries. Personal safety equipment can also help. Helmets, eyewear, hard hats, vests and other protective clothing can protect against injury.

Types of Forklift Accidents

Accidents vary according to the kind of forklift and the job the forklift and driver are performing.

Some forklift hazards are:

- Driving off a loading dock

- Falls between loading docks and trailers

- Falls from lift tines or elevated pallets

- Collisions with pedestrians

Forklift Safety Upgrades Protect Workers

OSHA regulates forklift operations and outlines rules for other type of heavy equipment. These rules protect operators and pedestrians. Because of the convoluted nature of OSHA regulations, it can take a safety specialist to understand and comply with all the safety rules.

Guidelines, however, are just the beginning. Employers must go beyond recommendations to protect workers from accidents. Plant upgrades in combination with training are two of the best ways to reduce the risk of accidents. Upgrades include:

- Equipment guarding

- Machinery emergency shutoffs

- Protected walkways for pedestrians

- Covers or restrictions on openings and holes

Storee is an experienced safety contractor. We can design and build safety upgrades to protect your workers from accidents.

The High Price of Accidents

OSHA reports that every year forklift accidents kill 85 people. Many if not most accidents are preventable by either training, personal safety equipment and more emphasis on forklift safety.

It’s impossible to gauge the emotional toll of a workplace death on co-workers and family. Other costs can be measured.

Here are some of the business costs associated with injury accidents at work:

- Workers’ compensation

- Medical costs

- Legal services bills

- Hiring and training employees

- Overtime

- Productivity loss

- Equipment repair

- OSHA fines

Our Experts Can Raise Forklift Safety

The first step to an accident-free plant is worker education and upgraded personal safety equipment. OSHA lays out work training recommendations here.

Our safety experts will assess your plant, identifying areas that put you and our workers at risk. We can repair or build new guarding and recommend personal safety equipment to increase the separation between forklifts and pedestrians. As an experienced industrial contractor, we can make changes with minimal disruption to your production line.

Storee has been partnering with businesses since 1966. Safety is one of our focus areas. Our Springfield, Missouri family-owned company is committed to keeping everyone safe.

For more than 50 years, we have worked to increase the forklift safety and make accidents a thing of the past.

Contact Storee to get started on upgrades that save lives. 888-736-2032.