Plant Optimization: The Bare Essentials for Reaching Efficiency

Most manufacturing facilities think they’re operating at peak efficiency. A simple audit would show they are not.

For one, factory managers need a dependable metric for identifying gaps in efficiency. The current standard are things like P/L reports or monthly operating reports, but none give them the information they truly need.

This evaluation process has been described by a Harvard Business Review article as “monitoring a distant activity through a thick, fogged window”.

Basically, it goes back to the old adage: when it comes to measuring efficiency, most factory managers can’t see the forest through the trees.

The most common pitfall for plant managers

Determining efficiency in a factory is quite simple: balance the ratio between output and input.

As of now, most handle just fragments of what makes total efficiency.

For example, one plant needs to improve its labor hours and wage costs. To solve this, the plant may replace the labor with equipment. The plant may not develop skills and systems though to realize the full potential of the machines, and operations will not function at peak efficiency.

What plants don’t realize is that buying machinery won’t solve all your problems. You have to manage their implementation. The investment is not just in the cost, but how carefully you manage its integration.

Ultimately, you as a plant manager are responding to changing customer demands and technological opportunities. Yes, it requires change, but not confusion.

Much confusion and inefficiency at a plant is generated internally.

Confusion is like static. It keeps you from seeing things clearly. It’s one of the major barriers when optimizing your plant’s efficiency. That’s why companies bring on a third party to optimize their plant operations.

Plant performance monitoring

Not many plants have a firm handle on their monitoring. This is why profit opportunities go unnoticed and equipment malfunctions seem spontaneous.

Without proper plant performance monitoring, you open yourself to always playing “catch up”.

When we optimize a plant, this is what we offer:

- Identify optimal equipment and proper operation

- Form action plans to stay proactive on maintenance

- Anticipate problems before they cause major disruptions to operations

- Enhance in-house monitoring procedures

- Implement proper data tracking systems

Eco-friendly upgrades can make your plant more efficient

Adopting greener practices in your warehouse can improve your company’s bottom line. Energy efficient practices can reduce costs, improve employee safety and health and decrease waste.

If you want a more eco-friendly business, consider introducing some of the following practices into your warehouse design and management:

ELECTRICAL UPGRADES

Outdated electrical systems waste energy. Upgrading to a new system will reduce consumption, though you must hire an electrical contractor who can develop a streamlined design with minimal downtime.

IMPROVED LIGHTING

Well-designed lighting can both cut your power bills as well as improve safety and productivity. A lighting designer can make a thorough assessment of your warehouse and draw up plans for a new system. Effective light placement and high-efficiency bulbs should be part of the design, as well a compliance with safety codes.

REDUCE AND REUSE MATERIALS

Most warehouses use a lot of packaging materials. Reducing shipping supplies can help you lower the cost of materials. It can also reduce shipping costs and the resources needed to move products within your facility. Here are some ideas to reduce extra packaging:

- Identify areas of waste and make changes to eliminate excess packaging.

- Choose biodegradable materials. Using more eco-friendly materials reduces pollution and minimizes your employees’ contact with potentially harmful substances.

- Reuse materials such as pallets, plastic totes and shipping supplies.

- Recycle materials you can’t reuse.

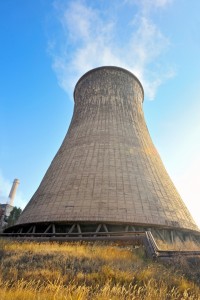

Process design for chemical engineering plants

We understand chemical industries are highly complex and often involve several businesses and systems.

Optimizing these processes comes down to effective resource management.

In chemical engineering, when you organize and exploit your resources properly, you see processes become more streamlined.

As you know, chemical engineering does not happen in isolated systems. Chemical processes can blend into different environments. At Storee, we work with chemical engineering plants to help them merge interactions and make this process more cohesive.

This is more important now than ever given the tighter regulations on environmental concerns. Our recommendations always keep this at the focus.

Plant optimization in action

One successful case of plant optimization came from an ethanol plant.

Their problem was obvious from the start: the plant was built on a tight budget, and their plan to recoup costs was to minimize energy by reducing equipment use.

To deal with a fluctuating economy, they had to lower their energy costs, which was difficult given the interconnectedness of their system. These decisions also had an effect on operations.

A third party company was brought in, and solved this by integrating a pinch model. The challenge came in that their existing equipment was not designed for it.

A mass and energy balance was developed as well as a concept energy recovery model. Certain equipment pieces—like mash trains, flash tanks and vent coolers—were replaced to reduce energy.

The outcome was 12.5% reduction in steam and 20% drop in natural gas usage. The ethanol plant was able to increase production and reduce downtime, and is still profitable to this day.

Optimized process design

One of our production improvement projects at Storee came when we had to install a hammer mill in an existing production area. It was a 22,000 pound machine that required a reinforced concrete foundation. A project of this scope forced the plant to be out of production.

We compressed the project into a 10-day completion. To accomplish this, we used detailed project task scheduling and a specialized concrete pouring process. As an added benefit, we transported the production equipment to the plant maintenance area for needed preventative maintenance so we could take advantage of scheduled equipment downtime.

The benefits of outside contractor for plant optimization

The hardest part with your plant’s growth is keeping proper sight of your mission. This is where it helps to bring in a third party. It can be quite difficult to keep a firm handle on everything, and a comprehensive audit with cutting-edge tools could be the first step in getting your plant to operate at peak efficiency.

Industrial contractors familiar with your manufacturing processes are in the best position to provide this analysis. They understand your operations and have the expertise to evaluate your facilities. Using flow diagrams, they can help you achieve ideal facility infrastructure, improved equipment layouts, optimized overall plant size and offer a variety of alternatives and options.

After all, what good is a process if it isn’t properly implemented?

Storee works with you to deliver the best results for current and future operations by first identifying specific needs and solutions. Storee develops building or manufacturing concept drawings utilizing AutoCad Revit and BIM technology for clear presentation of planned improvements. This allows for full client and design team collaboration on final specifications for the best possible plan. With a firm concept in place the project can quickly proceed to construction completion producing a well developed solution with long term results.

Our methods are customized per your plant. We can work with you from design conceptualization to installing equipment, and provide ongoing support to eliminate confusion.

To schedule an initial consultation, contact us online. We are based in Springfield, MO, but also serve plants in Kansas, Arkansas and Oklahoma.